Tiling is not particularly complicated, but like most construction skills it has its own specific terms with very precise meanings and vocabulary. It's important to understand this vocabulary to be 100% certain that you understand all the potential technical issues, use an appropriate installation system, purchase the right products, and ensure that they are correctly fixed.

ANHYDRITE

The word Anhydrite is getting more common, as modern fast-track construction methods are adopted by more contractors. Flooring screeds featuring anhydrous Calcium Sulphate (CaSO4) are popular because they are very fast to lay. However, they can cause issues for subsequent tiling unless correct procedures are followed.

A moisture test is often recommended and, while some screeds are described as low latience or latience free, any laitance or barriers to adhesion should always be removed prior to tiling. This will also help the screed to dry out.

There are now products on the market that can be used directly on anhydrite screeds, without the usual surface preparation or drying time. Always check with the manufacturer before using such a product.

BACK BUTTERING

The primary method of applying tiling adhesive is directly to the wall or floor using a notched trowel. When a substrate is not completely flat or the back of the tile has deep indentations or a raised profile, it can become necessary to apply additional adhesive to the back of a tile using a buttering trowel, known as back buttering.

The notched trowelling and back buttering method is recognised as an industry best practice both to enable wet on wet adhesive connection to aid with bedding of the tile and, as tiles are becoming larger and larger, back buttering is often used to guarantee that 100% adhesive coverage - solid bedding - is achieved.

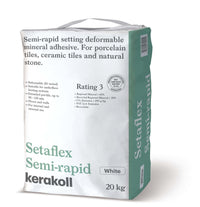

DISPERSION ADHESIVE

Dispersion adhesives are also called ‘paste’ or ‘ready-mixed’ adhesives. These easy-to-use formulations are classified as either D1 or D2.

- D1 adhesives are not water resistant and are used for dry internal wall tiling.

- D2 adhesives are suitable for internal wall tiling in wet areas such as showers, but not for total immersion conditions.

Reduced slip, an optional characteristic, is shown with a ‘T’ and extended open time (over 30 minutes) is shown with an ‘E.’ Therefore, an adhesive classified ‘D2TE’ is a water-resistant dispersion adhesive with reduced slip properties and an extended open time.

Dispersion tile adhesives are water-based and are particularly suitable for use with porous bodied ceramic tiles.

Fixing porous wall tiles

A rather close up image of 'ettringite', below

ETTRINGITE

The white staining you sometimes see around exposed external brickworks is caused by Ettringite. It's a natural mineral formed as a result of the reaction of calcium aluminate with calcium sulphate, both present in Portland cement.

Uncontrolled ettringite formation, due to its expansile nature, can damage cement-based mortars: a process often called ‘sulphate attack.’

To prevent this, Calcium Sulphate screeds must be allowed to dry to below 75% RH (Relative humidity), or less than 0.5% (moisture content by wet weight).

Correct priming is essential before installing tiles directly to Calcium Sulphate based screeds using cementitious-based tile adhesives, or a suitable uncoupling membrane can be used.

GLAZE

Ceramic tiles can be coated in various glazed finishes, including shiny high-gloss, clear/transparent, crystalline, matt low-gloss, opaque or non-transparent, and even speckled. The latter contains granules of contrasting colours.

Care should be taken when grouting glazed tiles and it is best to test a sample area before proceeding, incase the grout damages the glaze. For the same reason, the use of a hard plastic scraper for grouting purposes should be avoided.

MOVEMENT JOINTS

A Movement Joint is a stress-relieving joint used to compensate for movement of tiles and / or the substrate, by separating a large tiled area into separate tile fields to prevent cracking, bulging, or de-bonding. These joints should extend through tile, adhesive, and screed. They must be used in larger tiled floors and walls; and should be planned at the beginning of a project.

For floor tiling, BS 5385: Part 3 recommends that the maximum tile field should be no more than 10 metres in any direction but, in practice, movement joints may be required at intervals of between five and eight metres. This may be due to sources of potential thermal stress or when tiling over suspended floors.

For external tiling, intermediate movement joints are required at 3 metre intervals.

OPEN TIME

Open Times refers to the length of time after adhesive has been applied to the substrate during which it retains its ability to adhere to and bond a tile. An open time of 20 or 25 minutes is typical for most tile adhesives.

Open time should never be confused with pot life, which is the period of time during which an adhesive or grout, maintains its workable properties after it has been mixed. Never extend the pot life of any product by adding more water once the pot life is over.

RECTIFIED

Although all factory-made ceramic tiles are extruded or pressed to achieve virtually identical dimensions, the drying and firing processes cause shrinkage which varies minutely from tile to tile.

In order to assure absolute size consistency, tiles can be rectified after firing. This consists of machining each tile, with saws or grinders, to ensure that all tiles within a batch are precisely the same size. This can enhance the aesthetic appeal when using narrow joints or modular sized tiles with precisely aligned joints.

SLIP RESISTANCE

The level of slip resistance of floor tiles - the degree to which tiles resist slipping – is determined by measuring the coefficient of dynamic friction. The greater the amount of friction between any floor surface and the feet or shoes of a person walking on it, the less likely they are to slip. Slip resistance can be affected by contaminants, such as dust, oil or water, which act as a lubricating film.

Several methods are used to determine the slip resistance of floor tiles. The preferred method of both the Health and Safety Executive, and the UK Slip Resistance Group, is the Pendulum Test, which simulates the action of a slipping foot. This test is used by such standards as BS 7976 (pedestrian surfaces), EN 1341 (external paving) and EN 14231 (natural stone modular tiles).

THROUGH-BODIED

There are two types of porcelain tile: glazed and through-bodied. A through-bodied tile comprises a mixture of clay, sand and other natural materials, pressed and fired at a high temperature.

The term refers to consistency of composition throughout the body of the tile, with the colour and texture running through the full thickness of the tile. Such tiles are highly resistant to chips and scratches, and can be machined to create attractive edge detail, such as bullnoses.

With water absorption less than 0.5%, and high strength, through-bodied porcelain tiles are suitable for applications ranging from external domestic patios right through to heavy commercial installations.

WATER ABSORPTION

A tile’s porosity indicates the degree of water absorption of the tile’s body. This will determine the tile’s frost resistance; and thus its suitability for external use. It also gives a strong indication of its resistance to staining and clean-ability.

The higher the water absorption, the greater the tile’s proclivity to expand in wet/damp conditions. Ceramic tiles are classified according to their level of water absorption: the ratio of the weight of water absorbed to the weight of the dry tile, expressed as a percentage.

- Porous bodied glaze: More than 10%. Suitable for indoor use only.

- Medium water absorption: From 6 to 10%. Suitable for indoor use only.

- Semi-vitrified: From 3 to 6% . Suitable for indoor use only

- Vitrified: From 0.5 to 3%. Frost-resistant and suitable for external use.

- Fully vitrified (porcelain): Less than 0.5%. Fully frost-proof and suitable for external use.